Maintaining the Highest Level of Operational Safety, Efficiency, and Reliability

Purpose-Designed Parachute Maintenance And Inspection Equipment

See It In Action

Parachute Maintenance Systems

We pioneered this unique application, and excel in the design, development, and engineering of purpose-designed parachute maintenance equipment and controls.

Safe

Let the motorized lift bars do the work and prevent injuries commonly associated with manually operated parachute hoisting systems.

Efficient

Increase the operational efficiency of your paraloft tower with ParaDry®Systems. The system is easy to operate and doesn't require extensive personnel training.

Reliable

ParaDry®Systems lifts are designed and manufactured to withstand the elevated heat and humidity of a parachute drying tower. The system will operate continuously within that severe environment for decades.

Economical

We will design a system that meets the unique needs of your paraloft tower, enabling you to service the maximum number of chutes with minimum man-hours.

Our Products and Services

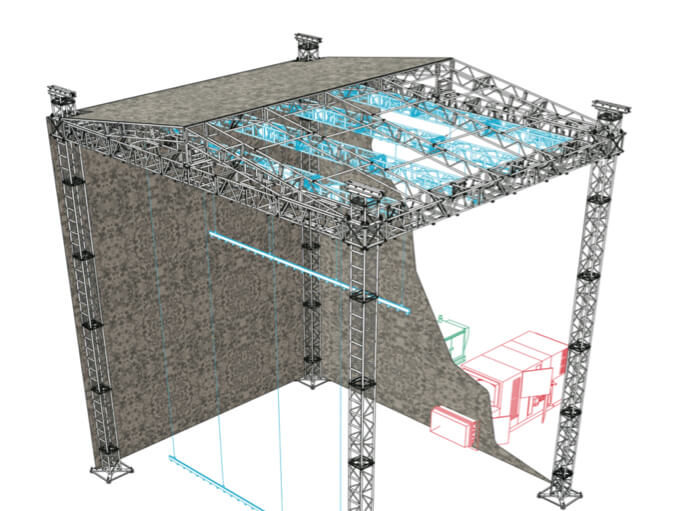

ParaDry®Systems Lift Configurations

Our team develops the optimal lift configuration by considering parachute type, dimension, quantity, weight, tower layout, and service cycle.

Learn More

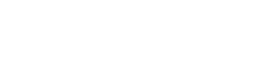

ParaRam™ Parachute Lifts

Ram-Air parachutes, a recent development in the military world, require specialized suspension equipment, like our ParaRam™ Lifts.

Learn More

ParaDry®Systems Expeditionary Tower

The Expeditionary Parachute Drying Tower is a temporary, mobile, and fully operational paraloft facility.

Learn More

Rigging Inspection & Review

Rigging inspections reflect prudent safety management. Let the professionals at ParaDry®Systems help you create the safest environment possible.

Learn More